What are engineered plans for motors pumps – Engineered plans for motors and pumps are essential blueprints that provide detailed instructions for the design, construction, and operation of these critical components. They play a pivotal role in ensuring the efficient and reliable functioning of motors and pumps in various industries and applications.

These plans encompass a wide range of aspects, including material selection, manufacturing processes, performance specifications, and testing procedures. By understanding the intricacies of engineered plans for motors and pumps, engineers and technicians can optimize their performance, minimize downtime, and ensure the safety and reliability of the systems they operate.

Introduction

Engineered plans for motors and pumps are detailed technical documents that provide comprehensive instructions for the design, construction, and operation of these essential components. They serve as critical blueprints for manufacturers, engineers, and technicians, ensuring the efficient and reliable performance of motors and pumps in various applications.

Types of Engineered Plans

Engineered plans for motors and pumps encompass a wide range of documents, each tailored to specific requirements and applications:

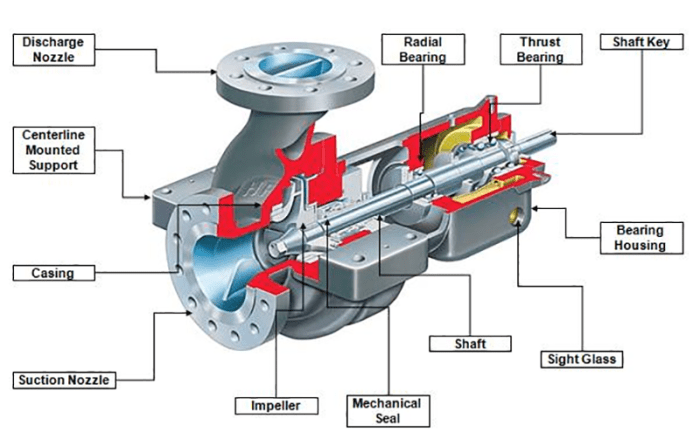

- Assembly Drawings:Provide detailed instructions for assembling motors and pumps, including component placement, tolerances, and connection details.

- Fabrication Drawings:Specify the materials, dimensions, and manufacturing processes required for fabricating individual components of motors and pumps.

- Performance Curves:Graphically illustrate the performance characteristics of motors and pumps, such as efficiency, power output, and torque.

- Wiring Diagrams:Artikel the electrical connections and circuitry for motors and pumps, ensuring proper operation and safety.

- Maintenance Schedules:Provide guidelines for regular maintenance and servicing of motors and pumps, extending their lifespan and optimizing performance.

Design Considerations

The design of engineered plans for motors and pumps involves careful consideration of several key factors:

- Efficiency:Plans must prioritize maximizing energy efficiency to reduce operating costs and environmental impact.

- Durability:Plans must ensure the longevity and reliability of motors and pumps, considering factors such as wear and tear, corrosion, and extreme operating conditions.

- Cost:Plans must balance performance and durability with cost-effectiveness, considering material selection, manufacturing processes, and maintenance requirements.

- Safety:Plans must incorporate safety features to prevent accidents and protect users, including proper grounding, insulation, and overload protection.

- Regulatory Compliance:Plans must adhere to industry standards and regulations, ensuring compliance with safety and performance requirements.

Materials and Manufacturing Processes: What Are Engineered Plans For Motors Pumps

Engineered plans for motors and pumps utilize a variety of materials, including:

- Metals:Stainless steel, aluminum, copper, and iron are commonly used for their strength, durability, and electrical conductivity.

- Plastics:Engineering plastics, such as polycarbonate and nylon, offer lightweight, corrosion resistance, and insulation properties.

- Ceramics:Advanced ceramics are employed for their high strength, wear resistance, and ability to withstand extreme temperatures.

Manufacturing processes for engineered plans for motors and pumps include:

- Casting:Molten metal is poured into molds to create complex shapes with high precision.

- Machining:Computer-controlled machines cut and shape components to precise tolerances.

- Fabrication:Sheet metal and other materials are formed and welded to create enclosures and other components.

- Assembly:Components are assembled according to the engineered plans, ensuring proper fit and function.

Testing and Validation

Thorough testing and validation are crucial for ensuring the accuracy and reliability of engineered plans for motors and pumps:

- Performance Testing:Motors and pumps are tested under various operating conditions to verify their efficiency, power output, and other performance parameters.

- Endurance Testing:Components are subjected to prolonged operation to assess their durability and reliability under extreme conditions.

- Safety Testing:Motors and pumps are tested for electrical safety, grounding, and protection against overloads.

- Field Testing:Prototypes or production units are deployed in real-world applications to evaluate their performance and identify any issues.

Applications

Engineered plans for motors and pumps find widespread application in various industries and sectors:

- Industrial Automation:Motors and pumps power machinery, conveyors, and other automated systems in manufacturing facilities.

- Water and Wastewater Treatment:Motors and pumps are essential for pumping, filtration, and treatment of water and wastewater.

- Automotive:Motors and pumps are used in fuel injection systems, cooling systems, and power steering.

- Aerospace:Motors and pumps are critical for hydraulic systems, fuel pumps, and other aircraft components.

- Medical Equipment:Motors and pumps are employed in medical devices such as surgical robots, dialysis machines, and imaging systems.

Recent Advancements and Future Trends

The field of engineered plans for motors and pumps is constantly evolving with technological advancements:

- High-Efficiency Motors:Advanced motor designs optimize efficiency, reducing energy consumption and operating costs.

- Variable-Speed Pumps:Pumps with adjustable speed capabilities improve efficiency and reduce wear and tear.

- Smart Pumps:Pumps equipped with sensors and controllers provide real-time monitoring and control, optimizing performance and reducing maintenance costs.

- Additive Manufacturing:3D printing technologies enable the creation of complex components with reduced lead times and improved customization.

- Sustainability:Engineered plans increasingly prioritize the use of environmentally friendly materials and processes, reducing the carbon footprint of motors and pumps.

FAQ

What are the key components of engineered plans for motors and pumps?

Engineered plans for motors and pumps typically include detailed specifications for materials, dimensions, tolerances, performance curves, and testing procedures.

How do engineered plans contribute to the efficiency of motors and pumps?

Engineered plans optimize the design and construction of motors and pumps, resulting in improved efficiency, reduced energy consumption, and enhanced performance.

What are the different types of materials used in engineered plans for motors and pumps?

Common materials used include metals (steel, aluminum), plastics, ceramics, and composites, each selected based on specific requirements for strength, durability, and corrosion resistance.